factory customized Small Refrigeration Air Evaporator - Enthalpy Wheels – Holtop

factory customized Small Refrigeration Air Evaporator - Enthalpy Wheels – Holtop Detail:

Main features of Holtop rotary heat exchanger

1. High efficiency of sensible heat recovery

2. Double labyrinth sealing system ensures minimal air leakage.

3. Self-cleaning efforts prolong service cycle, reducing maintenance cost.

4. Double purge sector minimizes carryover from exhaust air into supply air stream.

5. Life-time-lubricated bearing requires no maintenance under normal usage.

6. Interior spokes are used to mechanically bond the rotor’s laminations to reinforce the wheel.

7. Completed range of rotor diameter from 500mm to 5000mm, rotor can be cut into 1pc to 24pcs for easy transportation, various types of housing construction is available as well.

8. Selection software for convenient selection.

Working Principle

Rotary heat exchanger is composed of alveolate

heat wheel, case, drive system and sealing parts.

The exhaust and outdoor air pass through half of the

wheel separately, when the wheel rotates, the heat

and moisture are exchanged between the exhaust and

outdoor air. The energy recovery efficiency is up to

70% to 90%

| Wheel Materials |  |

| The total heat wheel is made by aluminum foils coated with 3A molecular sieve of 0.04mm thickness.  |

| Applications Rotary heat exchanger can built in air handling unit (AHU) as a main part of the heat recovery section. Usually side panel of the exchanger casing is unnecessary, except that bypass has been set in AHU. |

|

| It can also be installed in the ducts of ventilation system as a main part of the heat recovery section, connected by flange. In this case, side panel of the exchanger is necessary to prevent leakage.  |

| Note: casing type and segment quantity should depend on the application spaces as well as transportation capability and conditions at installation. Over segmentation will increase the assembly work, and overlarge size will cause diffculties in transportation. Application conditions - Ambient temperature: -40-70°C - Max face velocity: 5.5m/s - Max pressure on casing: 2000Pa |

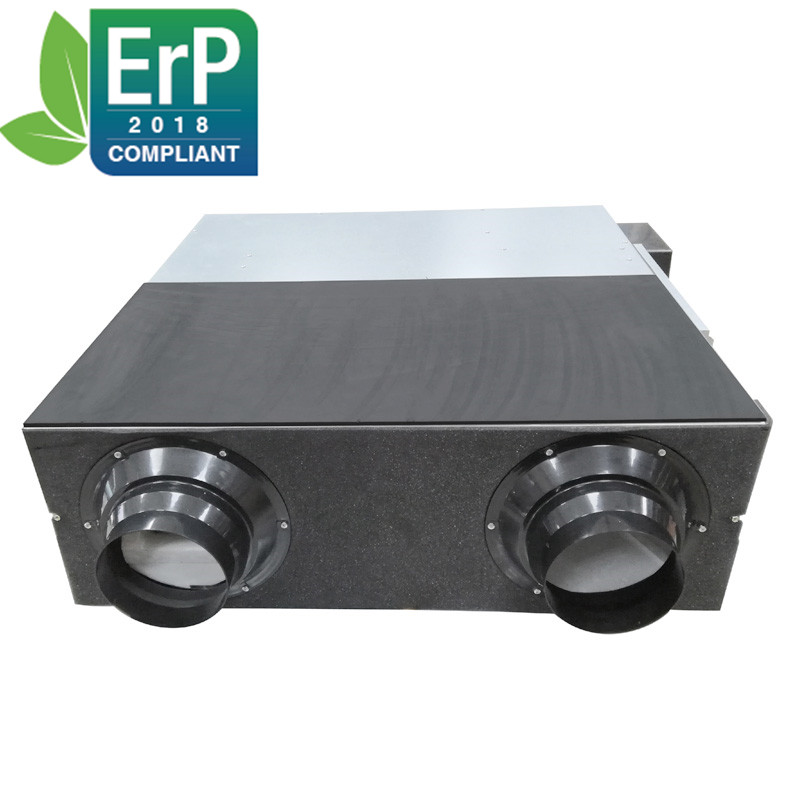

Product detail pictures:

Related Product Guide:

Automotive Cabin Air Filter Market by Key Players, Growth Factors, Regions and Applications, Industry Forecast By 2023 | Silent Ventilation Fan

Global Embedded System Market Report 2018-2025 with Profiles of Major Manufacturers (Renesas Electronics, STMicroelectronics, NXP(Freescale)) – Press Release | Whole House Air Exchanger

Adhering to your principle of "quality, assistance, performance and growth", we have now gained trusts and praises from domestic and international customer for factory customized Small Refrigeration Air Evaporator - Enthalpy Wheels – Holtop, The product will supply to all over the world, such as: Dominica, Dubai, kazakhstan, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in public placesand other industries. Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Single Room Heat Recovery Ventilator

Heat Recovery Ventilators

commercial heat recovery ventilator

Ductless Heat Recovery Ventilator

Heat Recovery Ventilator

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!